About Us

A company that understands the changes in the world and challenges the future through technological innovation.

BE THE BEST, BE THE FIRST

Servo Systems

Established to domesticate industrial servo systems,

the Servo Business Division has been committed to nationalizing control solutions across industries,

including automation equipment, machine tools, textile machinery, processing machines, bending machines, and printers.

-

- Leading the Domestic Servo System Industry

-

The HIGEN RNM Servo Business Division, originating from Geumsung Co., Ltd. (now LG Electronics) in 1963, has led the domestic development of servo systems through continuous research and development.

Additionally, as a leading company selected for the 100 core strategic technologies by the government's Special Measures Act to strengthen the competitiveness of the materials, components, and equipment industries, we are dedicated to the development of high-precision, high-output (290kW) servo systems for machine tools, and technology development for entering the global TOP 10 through domestic component verification projects and partnerships between component and demand companies.

-

- Providing Optimized Solutions Tailored to Customer Needs

-

HIGEN RNM is the only company in Korea that sells specialized products such as ultra-large 75kW servos and explosion-proof servos with all the certifications that have been developed.

Beyond high-voltage servo systems, we have also developed low-voltage servo systems operating at DC24~48V, expanding our application range to collaborative robots, AMRs, and various industrial fields.

-

- Supplying Special Purpose Servo Systems

-

The HIGEN RNM Servo Business Division, originating from Geumsung Co., Ltd. (now LG Electronics) in 1963, has led the domestic development of servo systems through continuous research and development.

Additionally, as a leading company selected for the 100 core strategic technologies by the government's Special Measures Act to strengthen the competitiveness of the materials, components, and equipment industries, we are dedicated to the development of high-precision, high-output (290kW) servo systems for machine tools, and technology development for entering the global TOP 10 through domestic component verification projects and partnerships between component and demand companies.

Explosion-Proof Servo Motor

FMA-EX Series

Due to current industrial safety regulations and recent fire issues in industrial facilities, the importance of explosion-proof certified products has been emphasized, leading to the development of explosion-proof servo motors.

Our explosion-proof motors have obtained both international certifications (ATEX, IECEx) and domestic certification (KCs) from the Korea Gas Safety Corporation, proving their reliability as domestically produced products.

- Features

-

Certifications : ATEX, IECEx, KCs

Grade : Ex d IIB T4, IP65

Control method : Speed/Position/Torque control

Capacity : 200W ~ 4kW

Encoder : 2,000 Pulse / Serial 17bit, ABS/INC

Application examples : Painting equipment, semiconductor equipment, petroleum/chemical equipment, etc.

-

200[W] / 220[V]

-

450[W]~800[W] / 220[V]

-

900[W] ~ 4[kW] : 220[V], 380[V]/440[V]

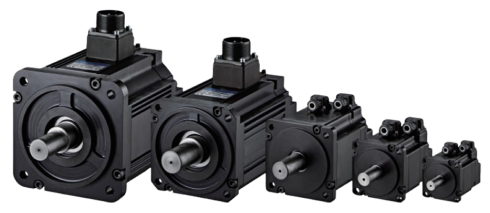

H1 Series

H1 SERVO DRIVE

The H1 Series was developed as a SLIM version compared to our existing series, responding to the industry's demand for more compact yet higher-performing equipment.

It features a high-precision, high-responsiveness 23-bit encoder for precise control, and has passed the EtherCAT conformance test, guaranteeing perfect compatibility.

- Features

-

Status window : 2-line OLED DISPLAY

IN/OUT : ST (pulse/analog type) RS422 / EC (network type) EtherCAT CoE

Encoder : Serial 23bit, Full-Closed dual feedback support

Servo safety functions : STO, over-temperature detection

Auto-tuning and multi-stage notch filter support

Capacity : 50W ~ 5kW

H1 SERVO MOTOR

- Features

-

High power density design and volume miniaturization considering heat dissipation

Production of motors with various specifications from 1,500rpm to 3,000rpm rated speed

Encoder : Serial 23bit

Capacity : 50W ~ 5.5kW

Application examples: Secondary batteries, inspection equipment, and other automation equipment

Injection Molding Machine Application

Development and Supply of Customized Servo Systems for Injection Molding Machines

Since 2014, starting with the EDA7000 model for the electric injection molding machine market, we have successfully applied the dedicated drive HLPD series. This has resulted in a more specialized servo for injection molding machines, increasing customer satisfaction and enhancing competitiveness.

With a diverse lineup of servo drives ranging from 2kW to 75kW capacity, we cater to electric injection molding machines from low capacity 30 tons to high capacity 850 tons.

We are growing together with our customers by dedicating our entire company to meeting customer requests.

Furthermore, based on excellent quality, we have succeeded in early stabilization, positively contributing to our customers' sales growth and brand image.

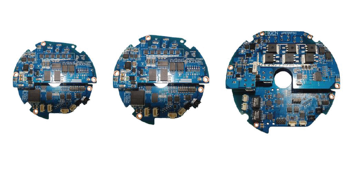

Direct to ProductsARES series

ARES-M

(Hollow Shaft Smart Actuator for Collaborative Robots)

- Network drive module for collaborative robot joints

- All-in-one hollow shaft module with drive-motor-reducer integration

- Supports EtherCAT, CANopen networks

- Compatible with 4 power ratings (100W/200W/400W/750W)

- Supports dual feedback

- Supply voltage : DC 48[V]

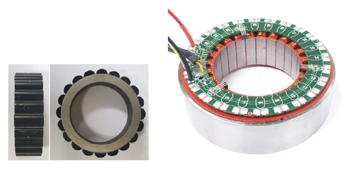

ARES-P

(Rotor and Stator for Hollow Shaft Smart Actuators)

- Modular rotor and stator components for robots

- Compatible with 5 power ratings (50W/100W/200W/400W/750W)

- Supply voltage: for DC 48[V]

- △ T: 55°C during operation

ARES-R

(Hollow Shaft Low-Voltage DC Drive)

- Drive for low pressure DC servomotor drive

- Supports EtherCAT, CANopen networks

- Compatible with 3 power ratings (maximum current: 10ARMS / 20ARMS / 80ARMS)

- Supports dual feedback

- Supply voltage: DC 48[V]

ARES-Q

(Standalone Low-Voltage DC Servo Drive)

- Drive for low pressure DC servomotor drive

- EtherCAT responds to CANopen network

- Compatible with 3 types of capacity (maximum current 10ARMS / 20ARMS / 80ARMS)

- Dual Feedback Support

- Supply voltage: DC 48[V]

Application Industries

Packaging Machines

Machine Tools

Logistics Facilities

Painting Machines

Injection Molding/Press Machines

General Industrial Machinery

Semiconductors

Secondary Batteries

Petroleum/Chemicals

Defense

Automotive Production Facilities

Displays