About Us

A company that understands the changes in the world and challenges the future through technological innovation.

BE THE BEST, BE THE FIRST

Robot Actuator

Established to domesticate the robot industry and standardize robot drive modules,

the robotics business division is dedicated to the domestication of automation solutions using various robots,

including factory automation systems and automatic logistics systems.

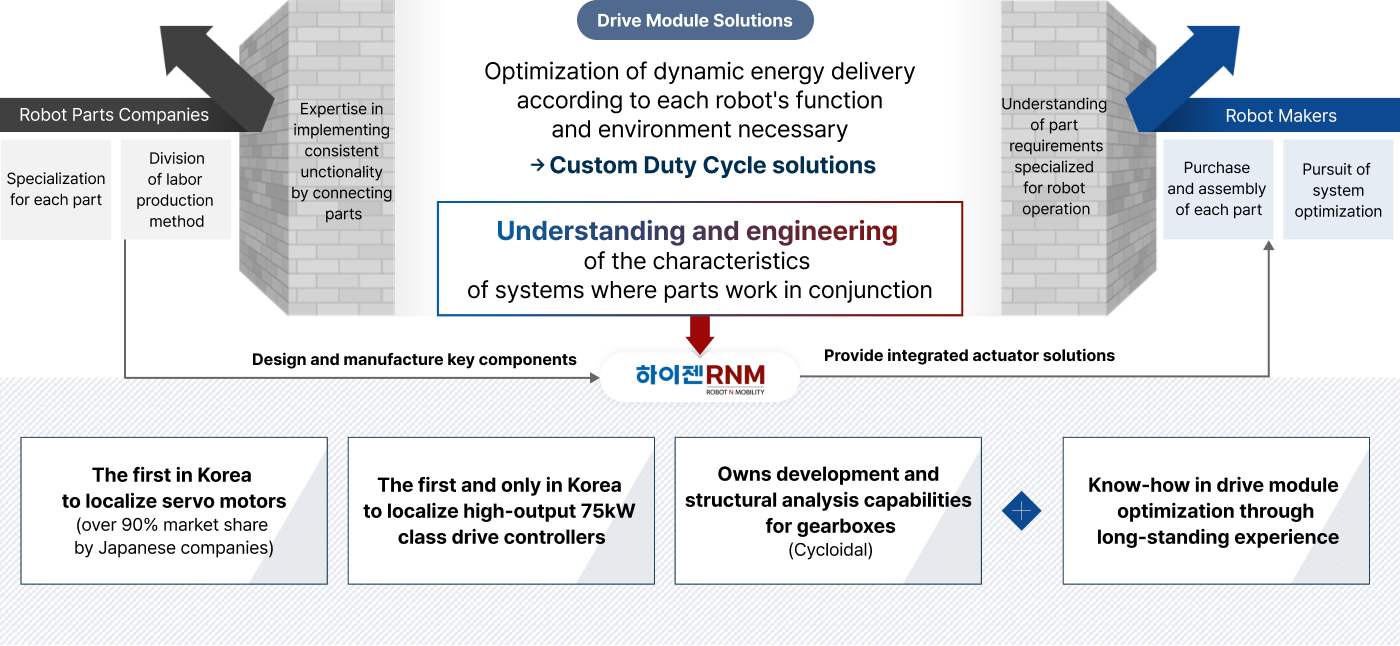

What is a Drive Module?

A key component responsible for the movement of legs, arms, wheels, etc., is crucial for a robot’s operation and determines the robot's movement and task performance.

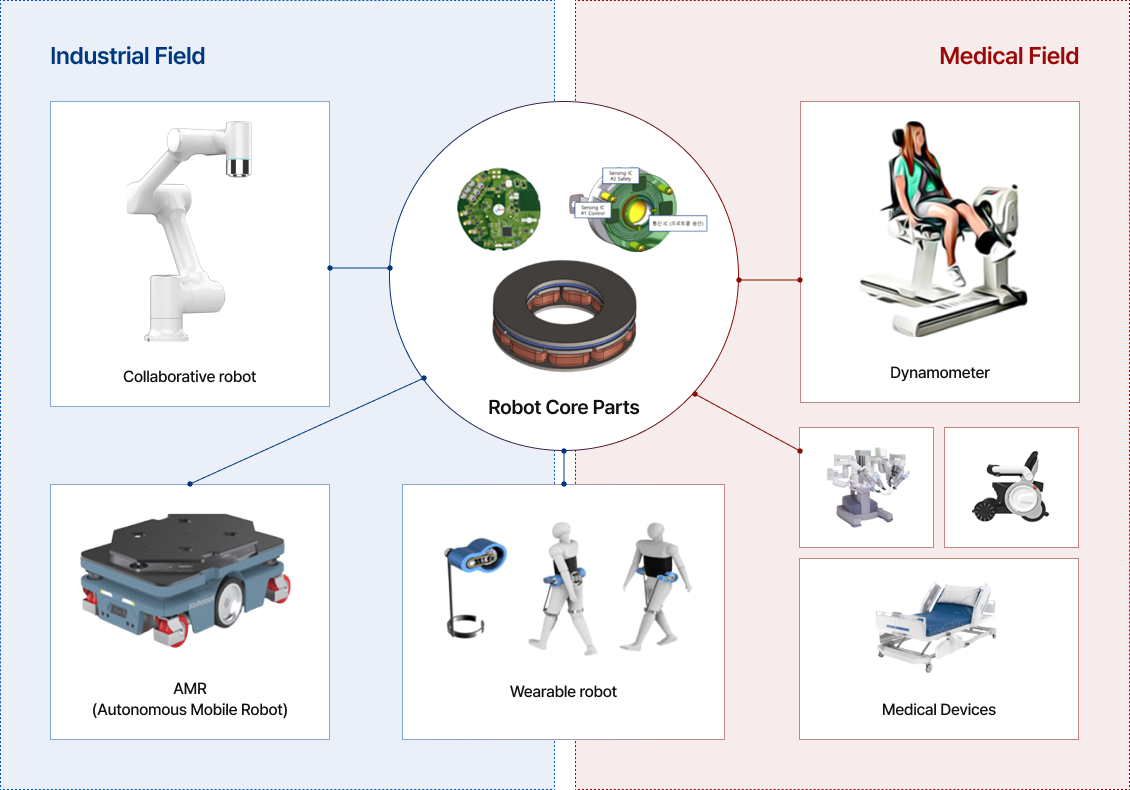

Application Examples

-

Collaborative Robots -

AMR -

Collaborative Robots

Core Components of Drive Modules

-

- Servo Motor Rotor+Stator

-

A device that drives a load in response to a control signal

-

- Drive Controller

-

Robot-specific control algorithms and drive

-

- Gearbox

-

Connects the motor and gears to change to the desired force and speed

-

- Encoder

-

Detects the position of robot joints and external impacts

Changes in the Paradigm of Robotics

Robots are evolving from performing simple repetitive tasks in controlled spaces to carrying out complex and challenging tasks in open spaces and sophisticated application environments.

| Industrial Robot | Collaborative Robot | Autonomous Mobile Robot(AMR) | Quadruped Robot | Humanoid Robot | |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Reference point | Fixed reference point (Fixed Base) | Moving reference point (Mobile Floating Base) | |||

|

|||||

| Number of active joints* (Number of drive axes) |

3~6 | 6~7 | Continuous a | 12 or more | 18~75 |

| Application environment | Structured environment |

◀ Low

Unstructured environment (complex environment)

High ▶

|

|||

| Simple repetitive tasks | Flexible collaborative movements with humans |

◀ Low

Complex movements

High ▶

|

|||

*Degree of Freedom (DOF): The number of variables required to describe the motion of an object

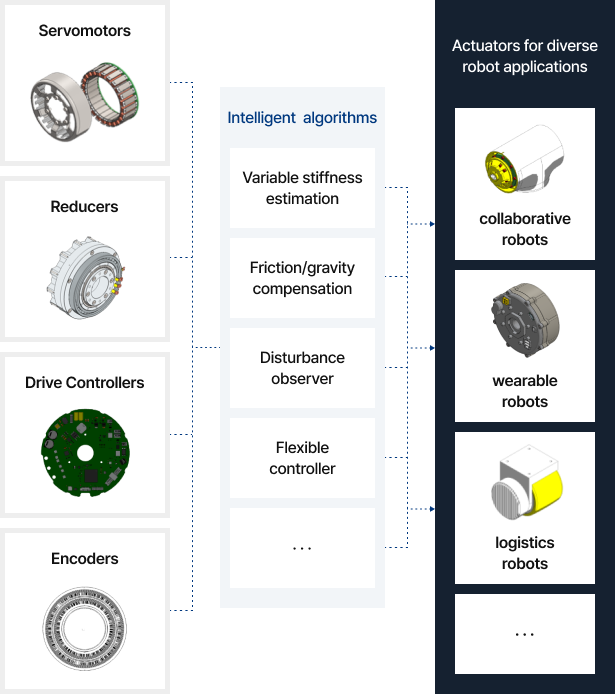

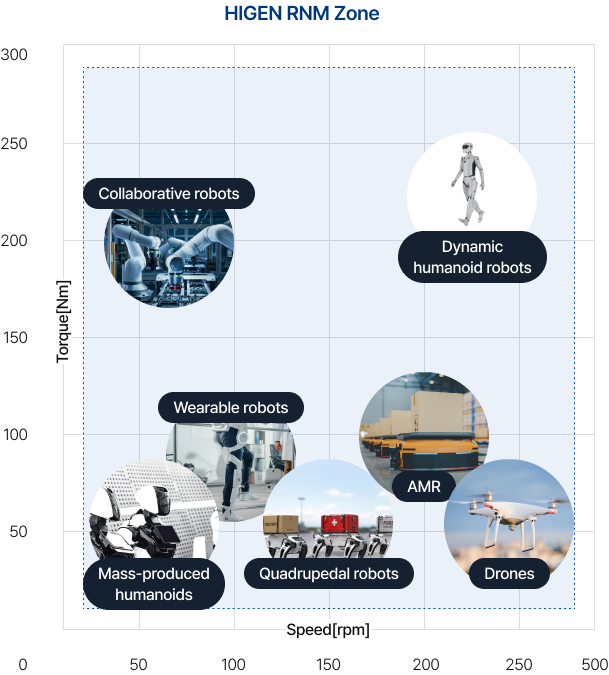

HIGEN RNM Robot Actuator Solution

"HIGEN RNM Smart Actuator" customized and optimized for various robot applications

HIGEN RNM Actuator solution

Providing actuators tailored to each robot

The reducers and motors that make up the actuator can be configured in various combinations according to the robot's movement and work purpose.

Additionally, the sensors embedded in the actuator detect speed, acceleration, and force, while the drive incorporates algorithms from the higher-level controller to enable distributed control of the robot's legs, arms, etc., enhancing the responsiveness of movements.

No.1 Actuator solution technical know-how

HIGEN RNM, a growth partner in the robotics industry

HIGEN RNM was the first in Korea to domestically produce servo motors and is the only mass production maker to develop a high-output 75kW class drive controller for the first time in Korea.

We also possess self-development and structural analysis capabilities for reducers (cycloid/planetary gears). Based on this business foundation, we provide Duty Cycle customized solutions using core components for actuators that we have designed and manufactured ourselves.

Application areas of our technology

-

Drone

-

Mobility for Defense

-

Mobility for Agriculture

-

Mobility for Industry

Application Industries

Automated Logistics Warehouses

Collaborative Robot Drive Modules

UAM

Smart Factory

Industrial Robot Motors